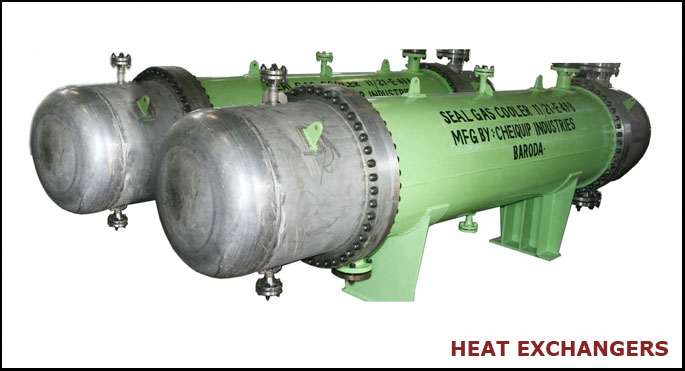

We manufacture Heat Exchangers like Coolers, Condensers, Evaporators, Chillers, Condensers etc for various application in Chemical Plant /Petrochemical Industry/Power Stations/Dairy Industry.

Manufacturing Process flows as enumerated below.

The Equipments fabricated by us are as per the Client's Specifications and Drawings confirming to ASME Sect. VIII & TEMA. Stage-wise & Final Inspection of the Fabricated Equipments has been carried out by Client's own Inspection Wing or Third Party Inspection Agency deputed by them.

|

| |

| Thermal Design of Heat Exchangers |

Client gives us the Thermal Design Parameters of the Fluids on both the sides. Based on the nature of the fluids, first of all appropriate MOC is selected. Again Based on the nature of fluids appropriate type of Heat Exchanger is selected. After the initial confirmation on the above from client, thermal design is carried out on internationally reputed softwares like HTRI/HTFS. The Heat Exchangers is optimized within the allowed parameters of Pressure Drop, using the allowed values of Fouling Factors, Fluid Velocity etc.

This design is submitted for initial approval from the client |

| Mechanical Design of the Heat Exchangers/Pressure Vessels. |

After receipt of approval of Thermal Design Calculations from client/HTRI Output Data from Consultant, Mechanical design based on applicable Codes like TEMA & ASME etc is carried out.

Complete Mechanical Design including Local Load Analysis on Nozzles as per WRC 107 is carried out on PV Elite/Bjack and thickness of various components is arrived at.

Drawings based on completed Mechanical Design are prepared & submitted to client/consultant for approval completely as per ASME & TEMA Codes.

Based on the approval given to the drawing and calculations, either manufacturing process is taken up or rework on drawings/design is carried out to achieve the closure on the same. |

| Procurement Activities |

| After approval of the drawings & calculations orders for Raw Material are placed with approved suppliers for various parts. Stagewise inspection of tubes/forgings at the Tube/Forger's manufacturing place is carried out, with witness of physical test and hand picking of tube/forging samples for chemical composition analysis by TPI at approved laboratory. |

| Processing of Raw Materials |

After approval of the forgings/plates/tubes duly identified by TPI, they are processed for machining/fabrication and drilling operations. Various Stages are offered to TPI as per the approved QAP.

Necessary QAP/WPS etc are in place and welding carried out using calibrated welding rectifiers. Calibrated Ovens for preheating of electrodes are used. |

| Post Weld Stage |

After carrying out the welding, visual check and Dye Penetrate check is carried out by us. Radiography is carried out by competent agencies hired by us.

Cases where Post-Weld Heat Treatment is required, the material is sent to outside agency for carrying out Heat Treatment before Radiography. |

| Final Dimensional & Visual Check |

| Entire Equipment is checked visually for any weld splatters, surface finishing etc. The equipment is checked dimensionally to confirm that all the dimensions within the allowable tolerances of the applicable code. |

| Final Hydro-test |

Final Hydro-test is carried out, after all the above stages are cleared. For carrying out the hydro-test we have

-

Hydraulic Test Pumps - Pressure upto 150 Kgs/Cm2

- Calibrated Pressure Gauges upto 150 Kgs/Cm2

Acid Cleaning/Sand Blasting/Painting is carried out after the client's inspection wing/third party inspector has cleared the equipment. |

| Documentation |

| Heat Chart, along-with material test certificates, Release Note & Internal Inspection Report along-with the Hydro-test and Guarantee Certificate are prepared for the every equipment. Soft Copies of the above are also available. |